In the realm of industrial automation, efficient and reliable communication networks are paramount. Profibus (Process Field Bus) has emerged as one of the leading protocols for industrial communication, facilitating the seamless exchange of data between various devices and systems. At the core of this robust communication standard lies the Profibus cable, a vital component that ensures the integrity and efficiency of data transmission. In this article, we delve into the world of Profibus cables, exploring their key features, types, advantages, and applications.

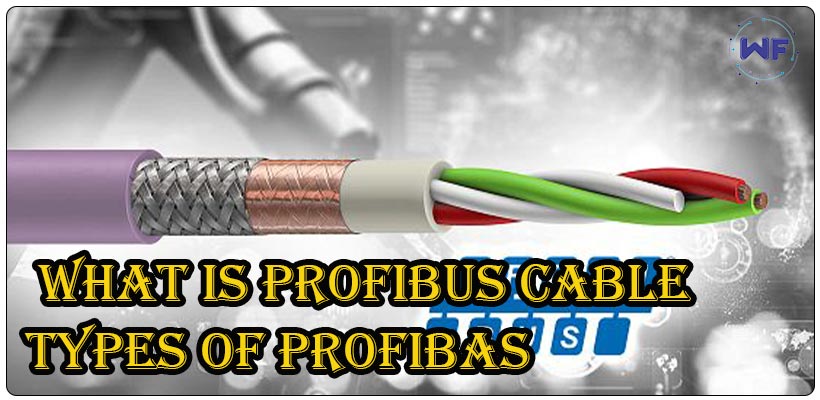

Understanding Profibus Cable

Profibus cables are designed to meet the specific demands of Profibus networks, providing a reliable physical connection between devices and enabling the transmission of data. These cables are responsible for carrying both power and data signals, allowing for efficient communication within industrial environments.

Types of Profibus Cables

1. Profibus DP (Decentralized Periphery):

Profibus DP cables are used to connect automation devices such as sensors, actuators, and programmable logic controllers (PLCs) in a decentralized manner. These cables typically support high-speed data transmission and can operate over longer distances.

2. Profibus PA (Process Automation):

Profibus PA cables are primarily utilized in process automation applications, specifically in hazardous environments. These cables adhere to stringent safety standards, such as intrinsic safety requirements, and are capable of transmitting both power and data signals.

Key Features and Benefits

1. Robustness and Reliability:

Profibus cables are designed to withstand the harsh conditions commonly found in industrial settings. They are resistant to electromagnetic interference (EMI), temperature variations, and mechanical stress, ensuring uninterrupted data transmission even in demanding environments.

2. High-Speed Data Transmission:

Profibus cables enable rapid data transfer, facilitating real-time communication between devices. This high-speed capability is crucial for time-sensitive applications, enabling prompt response and control within the automation system.

3. Easy Installation and Maintenance:

Profibus cables are available in various forms, such as shielded twisted pair (STP) or fiber optic cables, allowing for flexible installation options. Furthermore, the standardized connectors and straightforward wiring schemes simplify the installation and maintenance processes, reducing downtime and costs.

4. Scalability:

Profibus cables support the integration of a wide range of devices, allowing for the expansion and modification of industrial networks as per requirements. This scalability makes Profibus a versatile communication solution, adaptable to evolving industrial needs.

Applications of Profibus Cables

Profibus cables find extensive use across numerous industries, including manufacturing, oil and gas, chemical processing, automotive, and more. They are employed in various applications such as factory automation, process control, machine-to-machine communication, and distributed control systems. Profibus cables facilitate efficient data exchange, enabling seamless coordination among different components within industrial systems.

Profibus Cable Variants:

1. Profibus DP (Decentralized Periphery): Profibus DP cables are commonly used in factory automation and process control applications. They support high-speed data transmission rates of up to 12 Mbps and can operate over distances of several kilometers. The most commonly used Profibus DP cable type is the shielded twisted pair (STP) cable, which provides effective protection against electromagnetic interference.

2. Profibus PA (Process Automation):

Profibus PA cables are specifically designed for process automation applications, such as those found in the oil and gas, chemical, and pharmaceutical industries. These cables are suitable for use in hazardous environments and adhere to intrinsic safety standards. Profibus PA cables are capable of transmitting both power and data signals over long distances, typically up to 1.2 km.

3. Profibus FMS (Fieldbus Message Specification):

Profibus FMS cables are employed in systems that require longer transmission distances and slower data rates. These cables are typically used for data exchange between higher-level control systems and field devices, such as sensors and actuators.

4. Profibus MPI (Multi-Point Interface):

Profibus MPI cables are used for communication between programming devices and automation components during configuration, programming, and diagnostics. These cables typically have a lower transmission speed compared to other Profibus cable variants.

Key Factors to Consider when Choosing Profibus Cables

1. Cable Type:

Selecting the appropriate Profibus cable type depends on the specific application, environmental conditions, distance requirements, and data transmission speed. Consider factors such as cable shielding, impedance, and compatibility with the devices and systems being connected.

2. Cable Length and Topology:

Profibus networks can operate in various topologies, including point-to-point, multi-drop, and ring configurations. The cable length and topology influence the selection of cable types and the overall network design.

3. Environmental Factors:

Industrial environments often present challenges such as temperature variations, moisture, and exposure to chemicals. Ensure that the chosen Profibus cables are suitable for the intended environment and offer the required resistance to external influences.

4. Certification and Compliance:

Check for certifications and compliance with relevant industry standards to ensure the quality and reliability of the Profibus cables. Compliance with Profibus International guidelines ensures interoperability and compatibility with other Profibus devices.

Maintenance and Troubleshooting:

Regular maintenance of Profibus cables is crucial to ensure optimal network performance. Some key maintenance and troubleshooting practices include:

– Periodic cable inspections for physical damage, such as cuts, abrasions, or loose connections.

– Verifying proper grounding and shielding of cables to minimize electromagnetic interference.

– Performing cable continuity tests and checking for impedance mismatches.

– Monitoring cable terminations and connectors for proper seating and integrity.

– Utilizing diagnostic tools and software to identify and resolve communication issues.

By understanding the different Profibus cable variants, considering the relevant factors during cable selection, and implementing proper maintenance practices, industrial systems can harness the full potential of Profibus communication, enabling efficient and reliable data exchange within automation networks.

Conclusion

Profibus cables play a pivotal role in enabling reliable and efficient communication within industrial automation systems. Their robustness, high-speed data transmission, ease of installation, and scalability make them a preferred choice in various industries. As industrial automation continues to advance, Profibus cables will remain an essential component, driving the seamless exchange of data and empowering industries to achieve enhanced productivity, efficiency, and control.

3 Responses

Thank you

You’re Welcome